Vision

Included in all Subscription licensesDesigned to give your material new life

Turn any camera image into vectorized sheets with textures. And speed up the material setup on your waterjet machine with GigE cameras.

Trace material and texture from any camera

With the help of a photo station, four ArUco markers (small 2D barcodes) and any camera, we can analyze and convert your material into lines and arcs. - A groundbreaking way of importing traced material into IGEMS CAD/CAM.

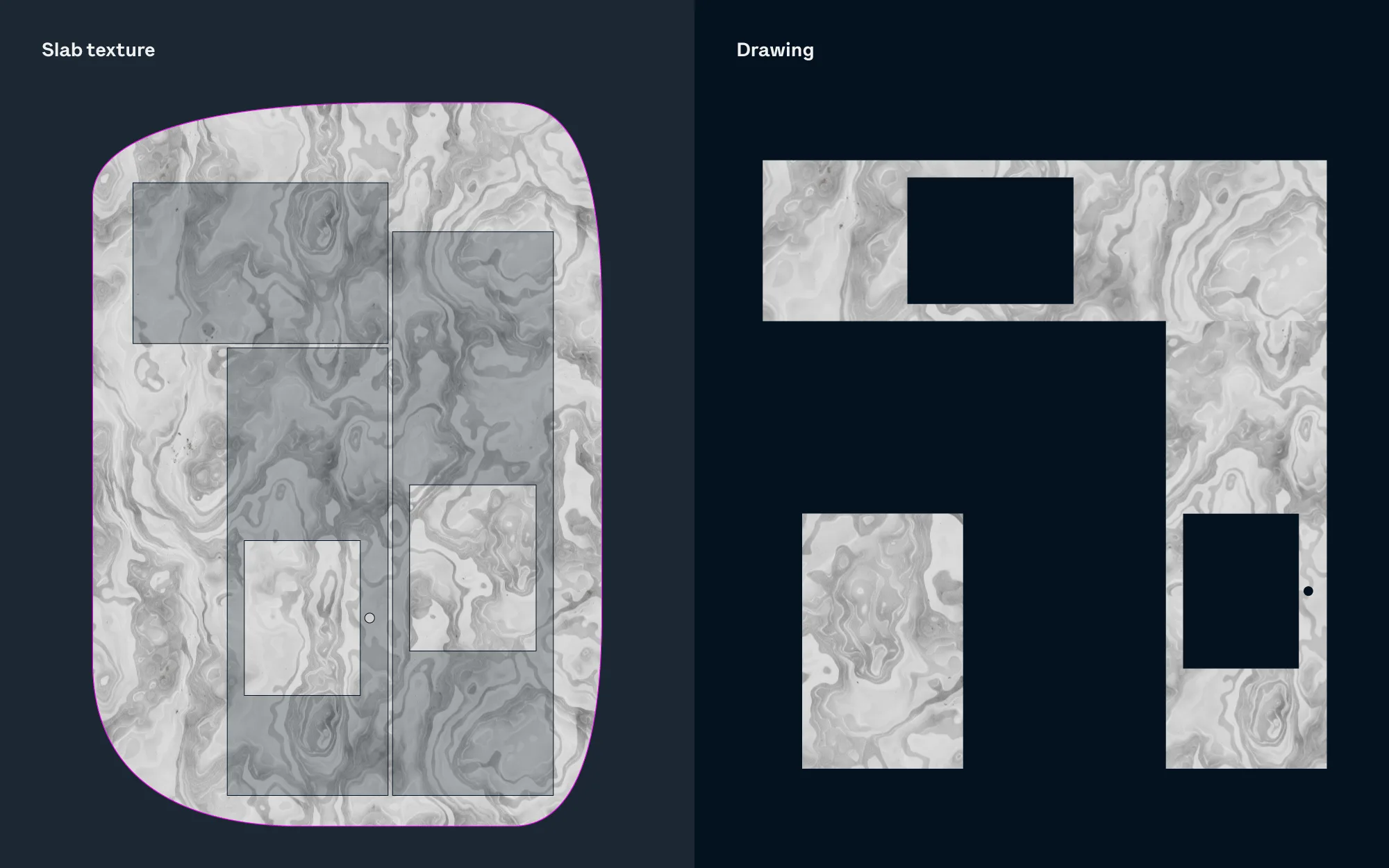

Photograph your stone slab in a photo station to automatically generate a sheet with its texture.

Photograph your stone slab in a photo station to automatically generate a sheet with its texture.-

The Slab Tracer opens up two great possibilities:

- Pattern matching.

- Making use of remnant sheets.

Pattern matching

For applications where the texture of your material is important, for example pattern matching kitchen tops from stone slabs. You want a quick and easy way of getting the geometry of the slab and its texture into IGEMS CAD/CAM. This is where Slab Tracer shows its real potential with options to import your material directly on the drawing our store it in the sheet database for later use.

Learn more about pattern matching Click and drag your parts on the slab to preview the pattern match.

Click and drag your parts on the slab to preview the pattern match.Remnant sheets

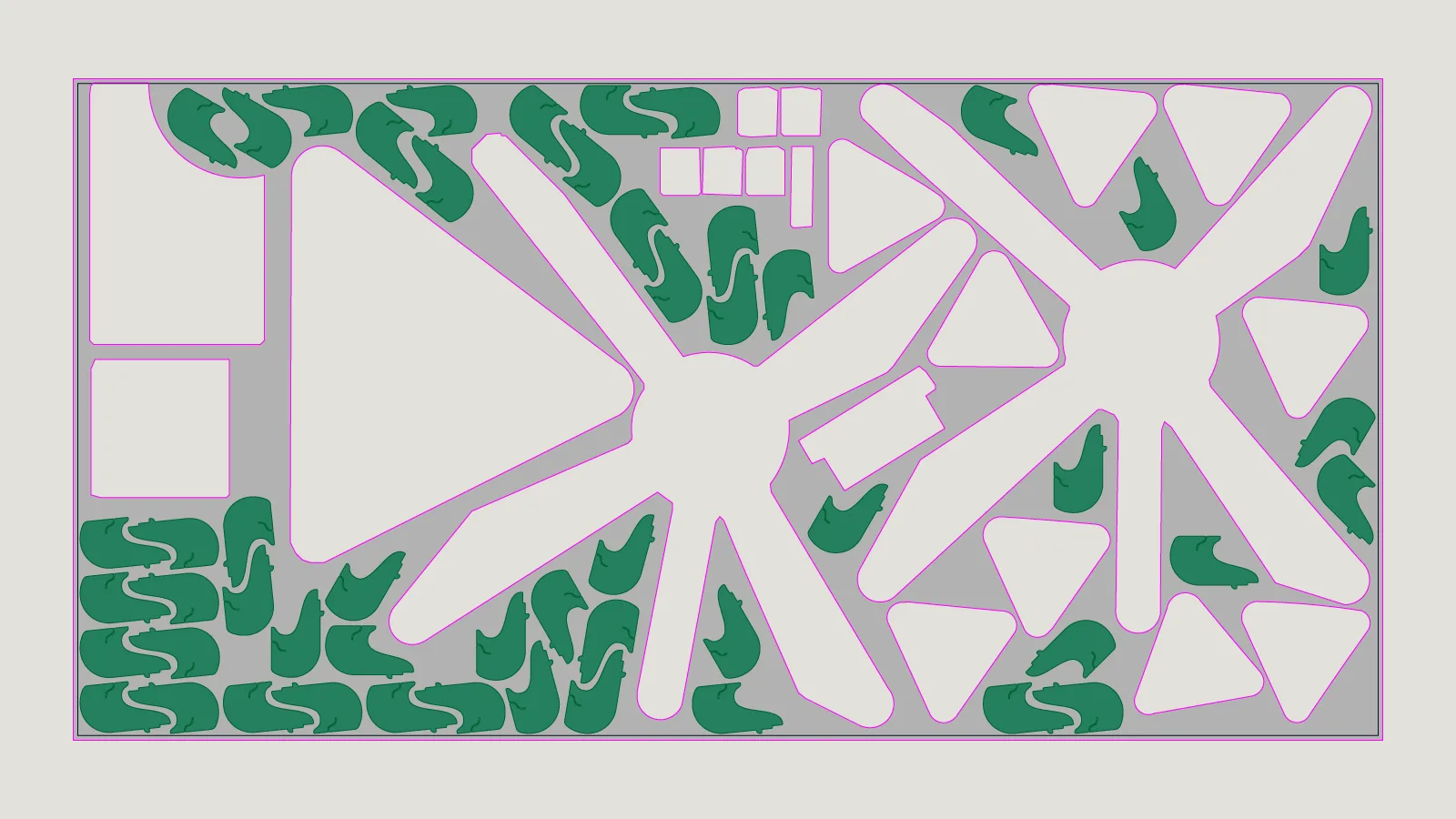

It's sometimes difficult to know if a remnant sheet still got some life in it. The time it takes to find out often outweighs the amount of parts you can get out of it. With IGEMS Slab Tracer you can automatically generate the whole geometry of your material and import it into IGEMS CAD/CAM.

Trace remnant sheets in a photo station with any camera.

Trace remnant sheets in a photo station with any camera. Use Auto Nest to fill the remnant sheet with parts.

Use Auto Nest to fill the remnant sheet with parts.By using IGEMS Auto Nest, you can easily nest parts onto the traced sheet within seconds. And there you have it. A fast and efficient way of getting more value from your remnant sheets.

Photo station setupKnow how and where to place parts

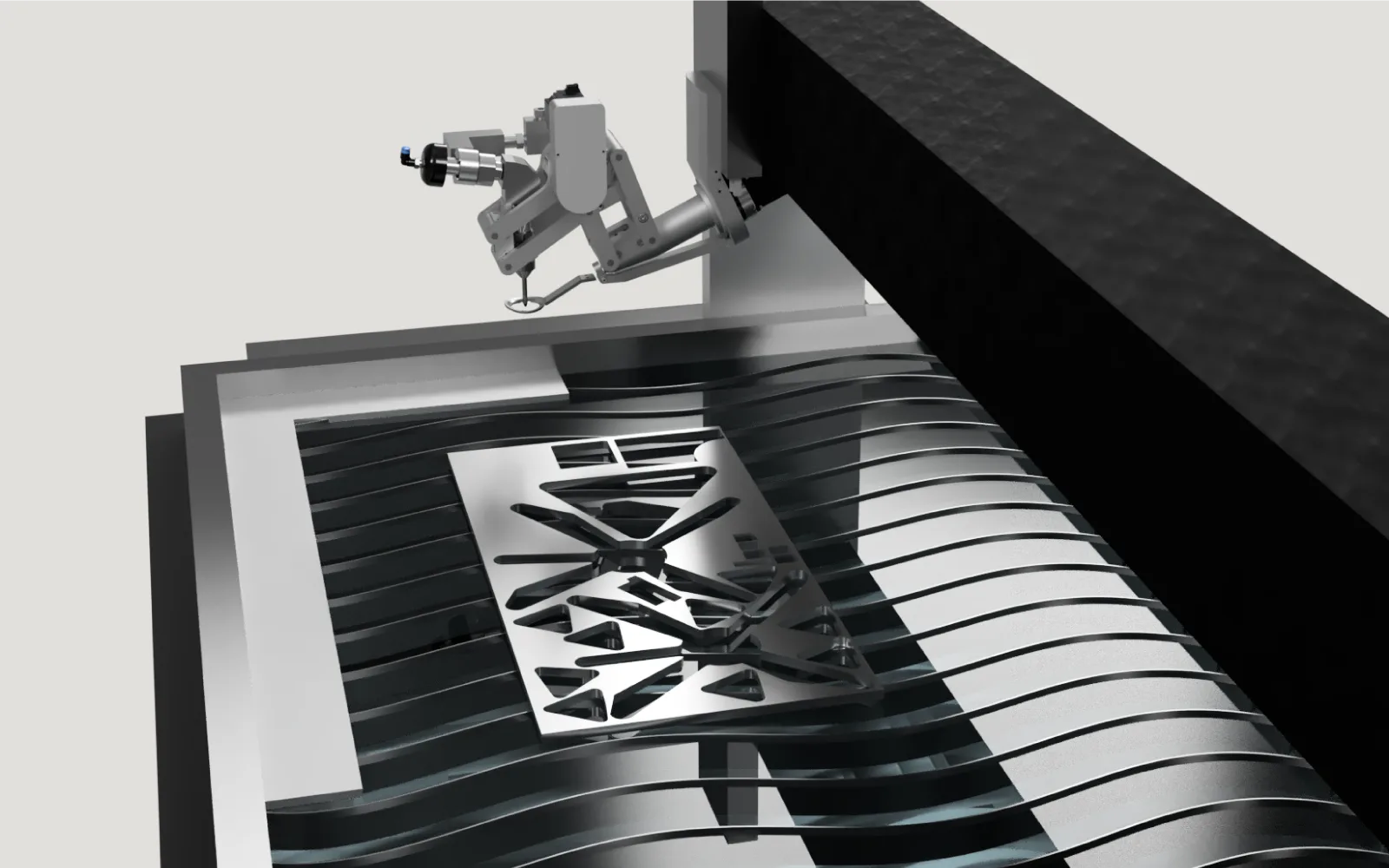

Anyone operating a CNC machine knows the time it takes setting up the material properly. Making sure your parts will fit the material and more importantly, making the machine start in the right position.

Our vision features does just that for you. With a calibrated GigE camera, you can place material on your machine table and import a top view image of it into IGEMS CAD/CAM. The image will be adjusted and scaled into 1:1 and you can easily place parts on the material on the image.

Photograph your material on the table from IGEMS CAD/CAM.

Photograph your material on the table from IGEMS CAD/CAM. A calibrated photo is inserted which you can place parts on.

A calibrated photo is inserted which you can place parts on.As illustrated above, a remnant sheet is placed on the table somewhere in the calibrated area. It's then photographed with the GigE camera and imported to IGEMS CAD/CAM with just one click.

How does it work?

The first thing we're after is a match between zero points on the machine and the CAD/CAM software. A connection between real life and the computer. Secondly, we'd want the correct scale and perspective of the image, so it represents the top view of the material in real life.

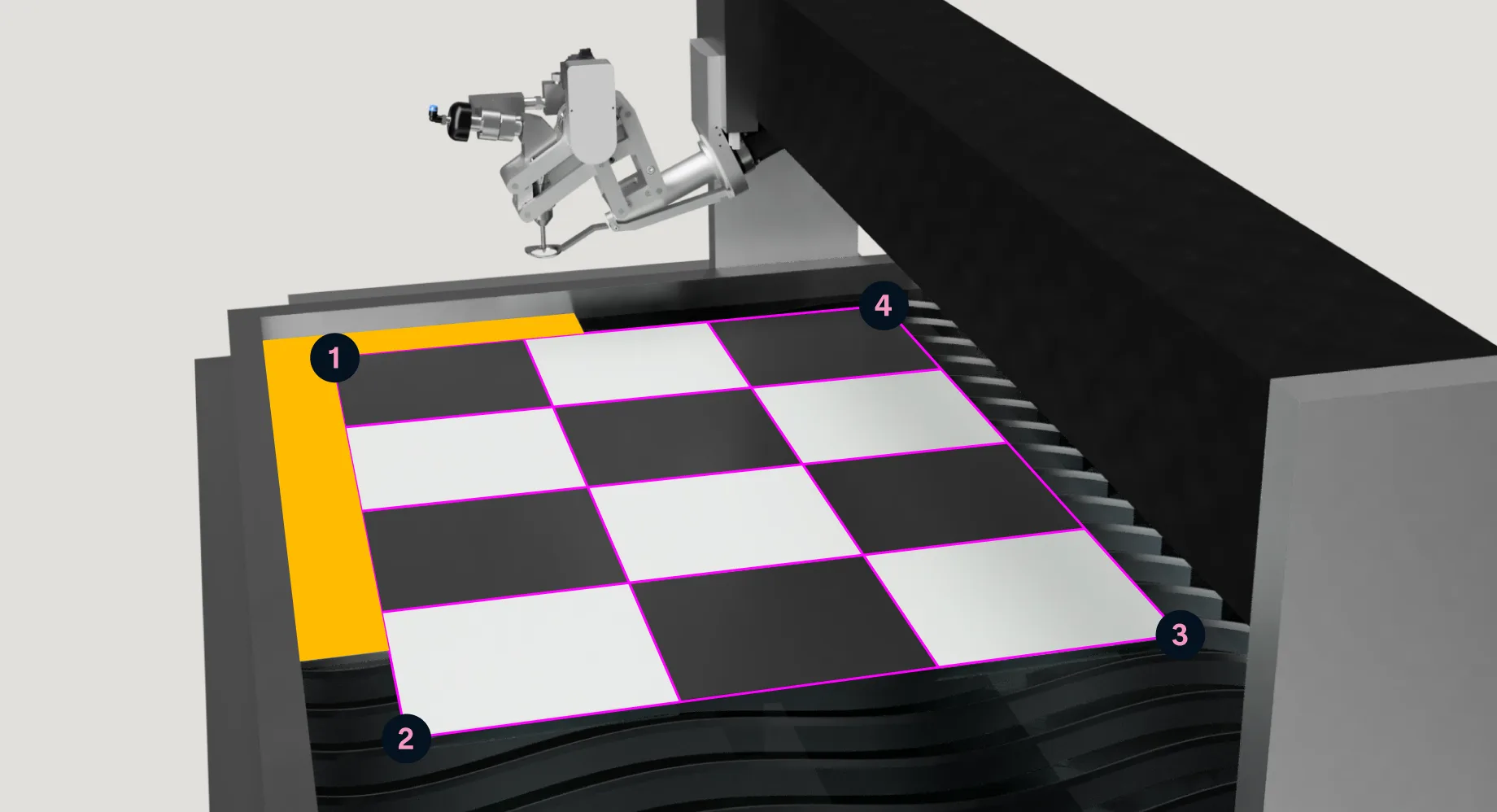

The zero point is collected in the first point you're picking from the calibration grid when calibrating the GigE camera (illustrated as "1" in the picture below). Easy breezy.

The scale and perspective calibration is a lot more difficult on the back end, but our programmers has made it easy for you. Just click the following 2, 3 & 4 points on the image below and the camera is calibrated. Some fine tuning might be needed, but it's just a click 'n drag operation of the grid points.

Calibrate the GigE camera with the help of a grid and an L stop. The size of the grid represents the image area that will be calibrated.

Calibrate the GigE camera with the help of a grid and an L stop. The size of the grid represents the image area that will be calibrated.It's important to calibrate the camera from the machine zero point. The position which says 0,0 on your controller in the machine coordinate system. Ultimately, you'd want an "L" shaped stop (highlighted yellow in the image above) where your calibration grid can rest in the 0,0 machine coordinate with 0° angle.

What camera should I use?

For this application where we import and calibrate an image from the machine table, you need to use a camera that operates on the GigE protocol. From what we know, any camera that supports GigE will work.