Innovation at every step

IGEMS CNC is developed exclusively for waterjet cutting. This means no unnecessary functions but a specialized, pinpointed solution, spiced up with our unique expertise, experience and support.

Key features

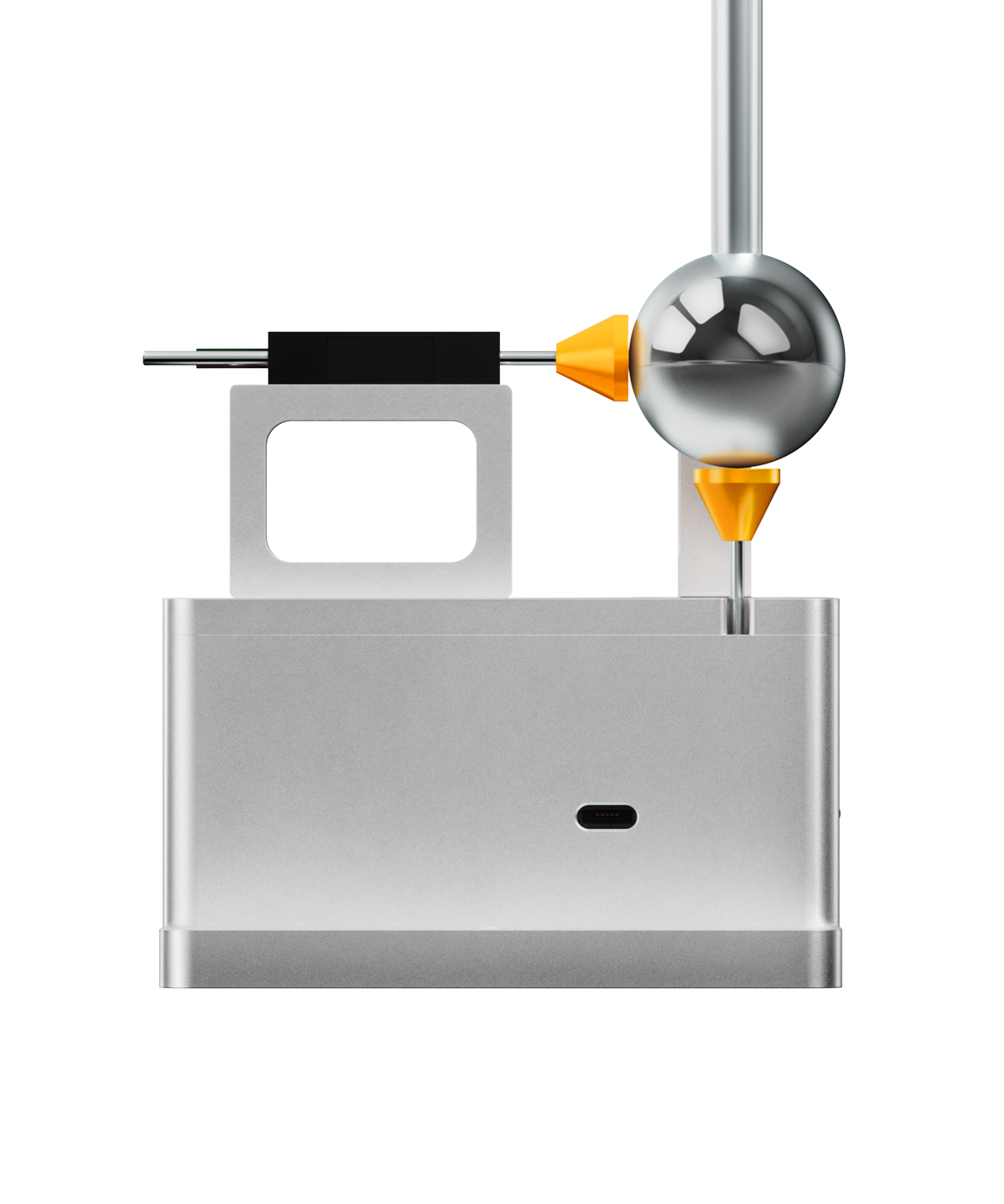

Automatic height sensoring

Minimize time,

maximize control.

Forbidden zone

Keeps you and your machine safe.

EtherCAT

Built for Beckhoff

Powerful HMI

Large files?

No problem!

Straighter

Straight focusing

tube in seconds.

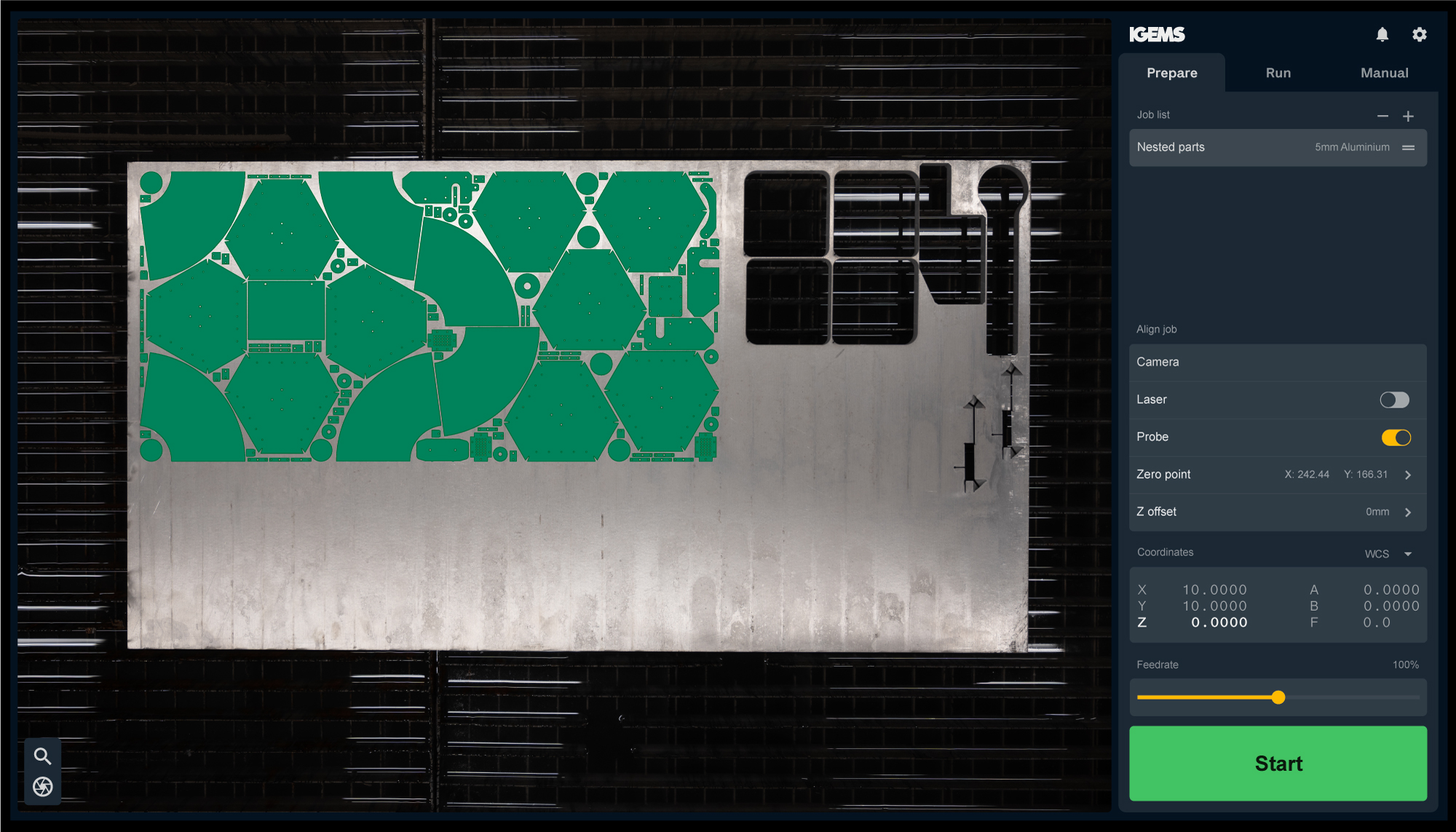

Snapper

Saves time and material.

Tap and start

Start anywhere on a

contour or rapid.

Rounder

Accurate bevels in minutes.

Special equipment

Supporting many tools.

More features

Compensation tables

Create compensation tables for individual tools such as Tilter to compensate for mechanical deviations.

Activate/deactivate water and abrasive while machine is moving

The XY movement is not interrupted by switching water on/off. This can give you nice leads.

Support for 64 motors and 10.000 iOS

Expandable and versatile system.

What's in the tank?

Get a report of what material and its quantity you have in your tank.

No stop between G93/G94

The machine does not need to pause and recalculate when switching from feeds in mm/min to inverse time. This eliminates washout of the jet in complex geometry.

Angle interpolation

Bevel arcs does not need to be split into many short line segments. The result is a smoother cut surface and a much shorter NC-file.

Job Center

Gives the operator information about Material, Thickness, Cutting time, Duetime already when choosing files to cut.

Find part in a file

If one part in your program turned out as scrap, you can easily isolate that part and recut it. Without having to generate a new program.

Progressive kerf

Automatic calculator for compensating the wear of your mixing tube and orifice.

Frequently asked questions

What CNC is best for waterjet cutting?

The best CNC for waterjet cutting is one that is designed completley for waterjet cutting. Many are using CNCs that are designed for other types of cutting machines and adjusted to "work" for waterjet cutting machines. But they often lack specific features required to match the high standard of IGEMS CNC.

What is waterjet cutting used for?

Waterjet cutting is used for many applications due to its advantages as a cutting machine. It will cut through most materials such as metals, stones, foods and even wood. When you consider to buy a waterjet cutting machine, make sure the software is allowing you to get the most out of your machine. Such as IGEMS CAD/CAM together with IGEMS CNC.

What materials can a waterjet cut?

A watejet cutter can cut through almost any material. From brittle ceramics to soft foams. The more homogenous the material, the better cutting result.

What is the best way to setup and place jobs on a sheet?

By using IGEMS Snapper you can save an immense amount of time. It's a camera located on the waterjet cutting machine which is calibrated to show a 1:1 sized image of the material on the IGEMS CNC. When taking a picture inside IGEMS CNC, you just click and drag the job to your desired position on the image.

Is it easy to calibrate the IGEMS Tilter?

Together with IGEMS CNC, Rounder and Straighter you can calibrate the Tilter within minutes! And the calibration will give you a perpendicular mixingtube together with a compensation table for the whole +-45° range.

What features are most important in a waterjet cnc cutter?

As with everything, it depends on the application. If you're cutting metal you most likely need a different setup than you would need for cutting ceramics. The takeaway from this is that it's best to look for a CNC that's ben developed for waterjet cutting and supports your application. Like IGEMS CNC.