Tilter

45° bevels & taper compensation

IGEMS Tilter is the worlds most versatile 5x kinematic mechanism since it handles both 45° bevels and taper angle compensation. Together with the compensation tools in our CNC, Tilter will give you the most precise and fast cutting on the market.

Why is Tilter the fastest option?

In the video below you'll see two types of 5x kinematic mechanisms cutting the same part with bevel and taper angle compensation. Both will have similar results on the bevel sides, but if you look closely on the straight edges, our Tilter is moving much faster. How is that?

It's because of mechanical advantages where the Tilter is not experiencing the same singularity problems other kinematic mechanisms are. An easy way to explain this is how much rotational movment each solution is doing when traveling from -1° to +1°. The Tilter only have to travel the 2° distance between -1° to +1° while other solutions have to rotate 178° for the same angle difference.

If you're looking for increased speed and quality, the Tilter is proven to be the best on the market.

Technical details

Frame material

Anodized 6082 aluminum

Bearings

Stainless steel

Total weight

≈ 12 kg

A axis gearbox

Harmonic Drive CPU 20

B axis gearbox

Spinea TS 70

A axis servo motor

Beckhoff AM8012

B axis servo motor

Beckhoff AM8011

Tilt range

±45°

Rotating tool center point

Mechanical

Suitable for

45° bevels and Taper angle compensation

Produced and assembled in Sweden

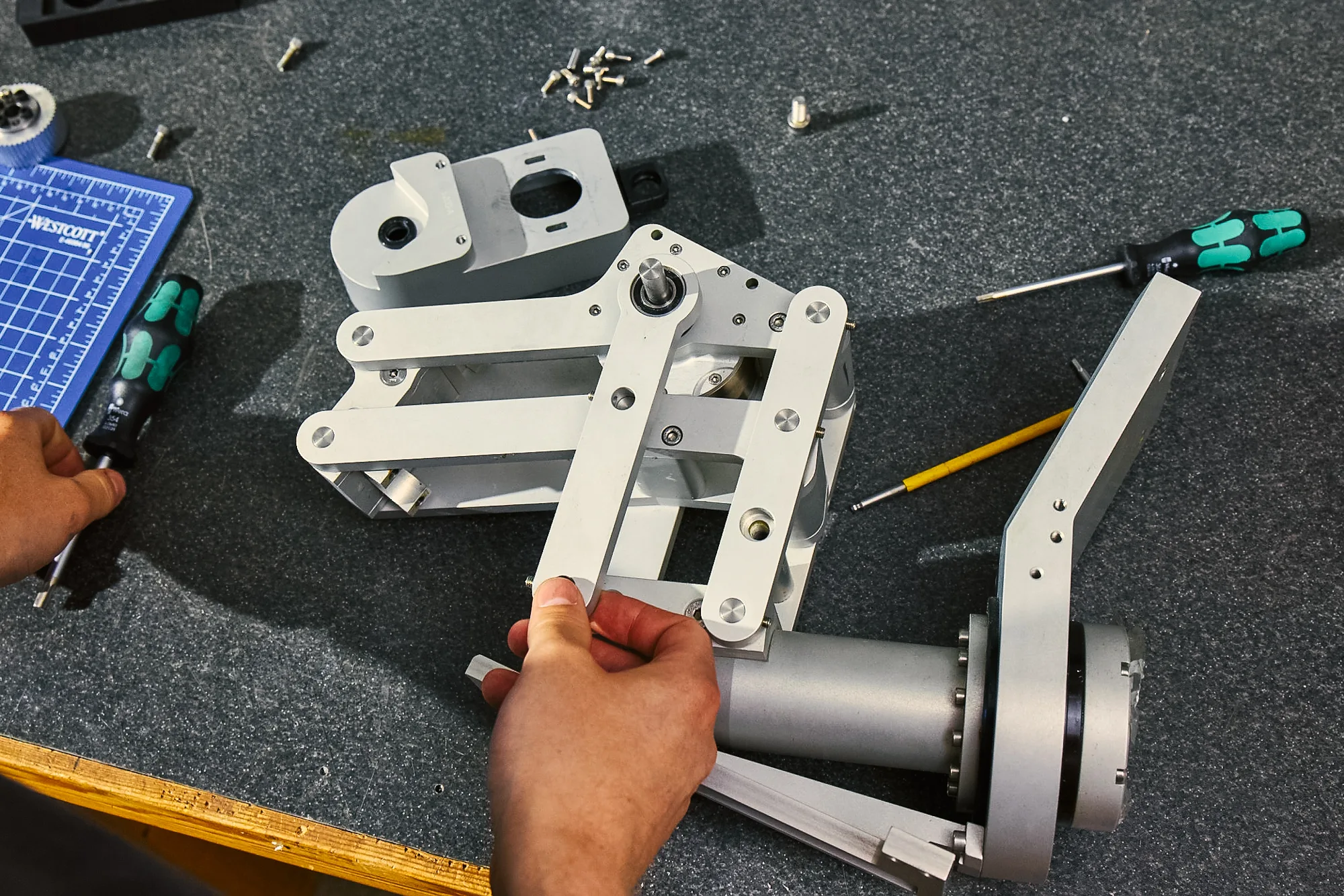

Every Tilter is produced by a fantastic mechanical engineer named Sven, just 10 minutes from our office in Sweden. When the components arrive to our workshop, Joel assembles them into the very best 5x mechanical mechanism for waterjet cutting there is.